Sisitemu z'ibikoresho zigira uruhare runini mu bikoresho bitandukanye bya mekanike, bigamije kohereza ingufu mu buryo bworoshye kandi bunoze. Ariko, imikorere y'ibikoresho ishingiye cyane ku buryoimigozi y'ibikoreshoNdetse no kutumvikana guto bishobora gutuma habaho kudakora neza, kwangirika no gucikagurika cyane, ndetse no gutsindwa gukomeye. Muri iyi nkuru, turasuzuma ibintu bigira ingaruka ku gukoresha neza imiyoboro y'ibikoresho no gusuzuma akamaro kabyo mu kwemeza imikorere myiza ya sisitemu y'ibikoresho.

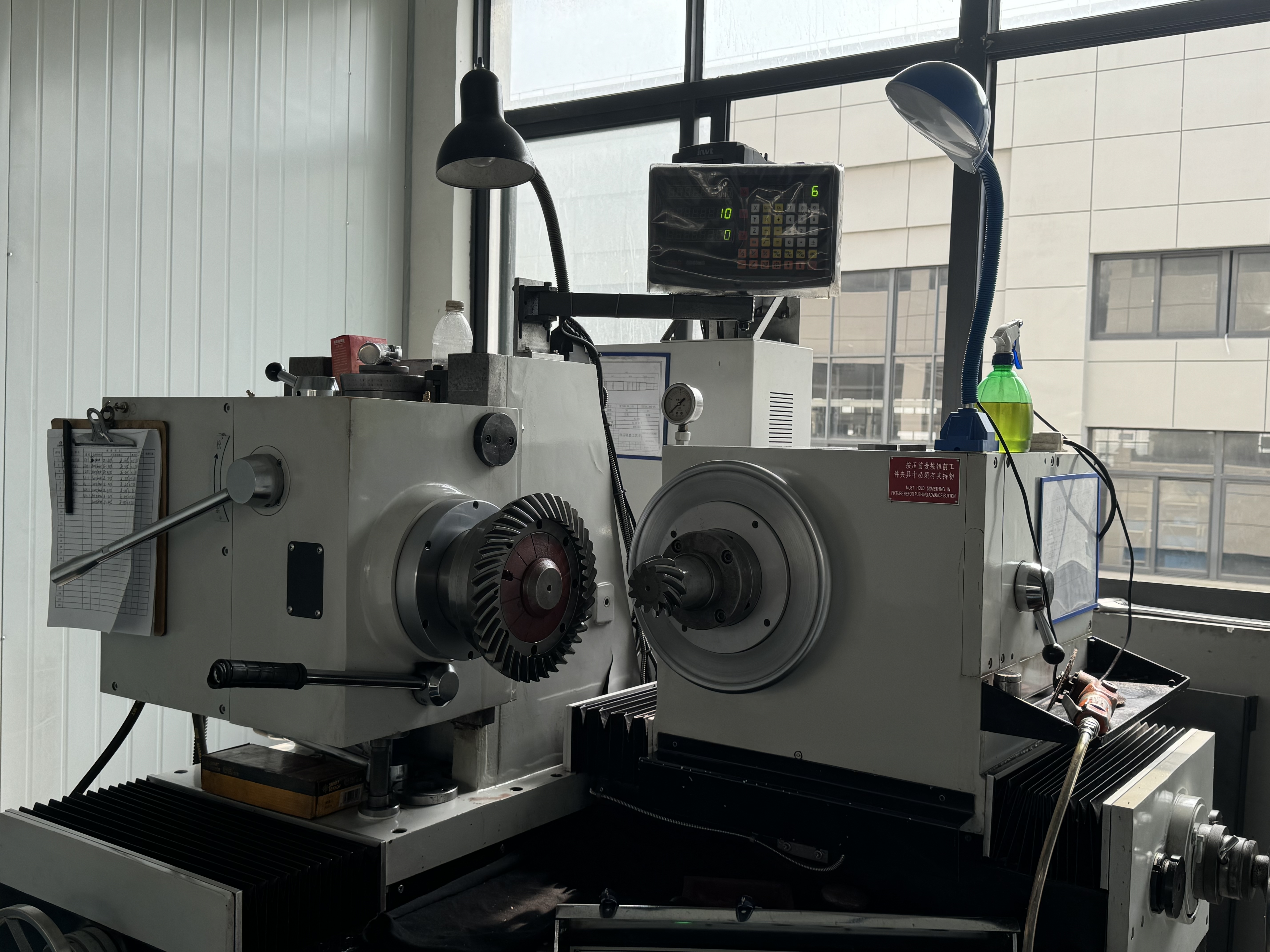

Umwirondoro w'amenyo ya Gear:

Imiterere y'amenyo y'ibikoresho ishobora kuba ari yo mpamvu y'ingenzi cyane igira ingaruka ku buryo amenyo y'ibikoresho akorana neza. Amenyo agomba kuba afite ishusho nziza kugira ngo ahuze neza kandi adatera imigeri myinshi. Gutandukana n'imiterere y'amenyo meza bishobora gutuma umutwaro utari mwiza, urusaku rwinshi, no kugabanuka k'ubushobozi. Ubuhanga bugezweho bwo gukora nk'imashini za CNC bwazamuye cyane ubushobozi bwo gukora imiterere y'amenyo y'ibikoresho neza.

Ubwihangane mu nganda:

Uburyo bwo gukora ibintu butuma habaho ubushobozi bwo kwihanganira ibintu, ibyo bikaba bishobora kugira ingaruka ku buryo ibikoresho bikoresha neza. Ihindagurika ry’ingano, imiterere y’ubuso, n’imiterere y’ibikoresho rishobora kugira ingaruka ku buryo ibikoresho bikorana mu gihe cyo gukora ibikoresho bikoresha uburyo bworoshye. Uburyo bwo kwihanganira ibintu bikomeye n’uburyo bwo kugenzura ubuziranenge mu gihe cyo gukora ni ingenzi kugira ngo ibikoresho bikore neza kandi birusheho gukora neza.

Guhuza no guteranya:

Gushyira hamwe no guteranya nezaibikoreshoSisitemu ni ingenzi cyane kugira ngo hagerwe ku buryo bwiza bwo guhuza imiyoboro. Guhuza imigozi, intera idakwiye hagati ya vitesi, cyangwa gushyiramo imiyoboro idakwiye mbere y’uko ishyirwamo bishobora gutuma imitwaro idakwiranye ndetse no kwangirika vuba. Kwita cyane ku mikorere yo guteranya, harimo no gukoresha ibikoresho byo guhuza n’imiterere y’imbaraga, ni ngombwa kugira ngo ibyo bibazo bigabanuke.

Gusiga amavuta:

Gusiga amavuta neza ni ingenzi mu kugabanya gushwanyagurika no kwangirika hagati y'amenyo y'ibikoresho. Gusiga amavuta nabi cyangwa adahagije bishobora gutuma amenyo y'ibikoresho yiyongera, gushyuha cyane, no kwangirika vuba. Guhitamo amavuta akwiye, hamwe no kubungabunga no kugenzura ingano y'amavuta, ni ingenzi cyane mu kubungabunga uburyo amenyo y'ibikoresho akoresha neza uko igihe kigenda gihita.

Amabwiriza agenga imikorere:

Imiterere y'imikorere ishobora kandi kugira ingaruka ku buryo ibyuma bikoreshwa mu gukora neza. Ibintu nk'ihindagurika ry'ubushyuhe, imitwaro y'ingufu, n'ubwandu bishobora kugira ingaruka ku mikorere y'ibikoresho.ibikoreshosisitemu zifite uburinzi bukwiye no gusuzuma imiterere y’imikorere iteganyijwe bishobora gufasha kugabanya izi ngaruka no kwemeza imikorere yizewe.

Kwangirika no Kwangirika:

Uko igihe kigenda gihita, verisiyo zishobora kwangirika no kwangirika, bigatera ingaruka ku buryo zikora neza. Uduce duto tworoshye, amavuta adahagije, cyangwa imizigo myinshi bishobora kwihutisha kwangirika no gutera impinduka mu miterere y'ibikoresho. Gusuzuma no kubungabunga buri gihe ni ingenzi kugira ngo hamenyekane kandi hakemurwe ibibazo byo kwangirika mbere yuko bibangamira imikorere y'ibikoresho.

Kugera ku ntego no kubungabungaibikoreshoUburyo bwo gukoresha mesh ni ingenzi kugira ngo sisitemu za mekanike zikore neza kandi zizewe. Mu gusobanukirwa ibintu bigira ingaruka ku buryo mesh ya mekanike ikora neza no gushyira mu bikorwa ingamba zikwiye mu gihe cyo gushushanya, gukora, guteranya no gukora, injeniyeri zishobora kunoza imikorere y'ibikoresho no kongera igihe cy'ubuzima bwa sisitemu za mekanike. Iterambere rihoraho mu ikoranabuhanga n'ibikoresho byo mu nganda, hamwe n'uburyo bukomeye bwo kugenzura ubuziranenge, bizakomeza kunoza uburyo mesh ya mekanike ikora neza kandi bigatera imbere mu buhanga mu by'imashini.

Igihe cyo kohereza: Gicurasi-07-2024